Cannabis Technology - The Rise of 3D Printed Bongs

Published on 1/9/22

3D printers are becoming increasingly relevant to many industries, and cannabis is no exception. A new era of cannabis accessories is dawning as people and companies are beginning to 3D print their bongs. Are you interested in adding a new type of bong to your collection? How easy is it to 3D print your own bong? What are the advantages of a 3D printed bong and should you give it a try? Let's find out.

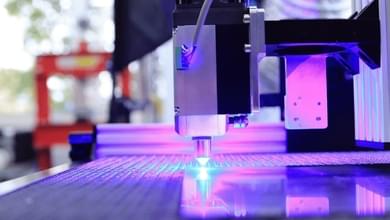

What is 3D Printing?

3D printing is an additive manufacturing process that requires a physical 3D printer and compatible computer software. There's a lot of different 3D printing software available, each offering an additional platform to create complex designs that are then created via a corresponding printer that builds the computer-generated design out of various materials. The digital design is sliced into hundreds of thousands of layers that the printer then produces in a modular fashion, one at a time from the ground up until the final product is complete. The process allows for highly intricate designs and can even include individual pieces like moving hinges and wheels. A wide range of materials can be used in 3D printing, including metals, graphite, and carbon fiber. However, plastic is still the most common material used.

Here's a list of some items known to be made with 3D printing:

- Movie props

- Architectural models

- Prosthetics

- Dental products

- Manufacturing tools

- Furniture

- Mechanical parts

- Eyewear

- Jewelry

The History of 3D Printing

3D printing has been around since the 1980s, with the first attempts credited to Japanese engineer Dr. Kodama. The process wasn't viably used by any industry until the 1990s, at which point it still cost hundreds of thousands of dollars for a 3D printer. The media picked up 3D printing in the 2000s, and it quickly became a very culturally relevant topic. With increased accessibility, industries began to use 3D printing, including the medical sciences, to create things such as model organs and prosthetics. The first commercial 3D printer for desktops became available in 2006, and DIY, at-home printers have since become increasingly common and affordable. The future of 3D printing is seemingly limitless. Homes have been built using the processes, along with functioning organs, bones, food, cars, and yes, bongs.

3D Printing and Cannabis

Unsplash

UnsplashIf a house and human organ can be created via 3D printing, it's no stretch of the imagination that it can be used to craft a functional bong. All the proper mechanisms to a bong - from the bowl to the central chamber, straight tube, and percolator - can be appropriately constructed so long as the digital design is accurate. As of 2021, 3D printing is still not used to mass-produce bongs (companies like PrintABowl launched in the 2010s and didn't make it long on the market). Only a few companies focus specifically on 3D printed products, like Print Puff Pass 3D Printing Smokeshop and Kayd Mayd. These companies offer prebuilt designs, but they also allow you to custom build your own pipe - one of the benefits of 3D printing. 3D printed bongs are beginning to take off on open-source creative sites where people upload their designs for bong molds for others to download and use. These websites include Thingiverse, YouMagine, and Yeggi.

How to 3D Print Your Own Bong

Even if you aren't overly computer savvy, it's becoming increasingly easy to print your bongs at home thanks to these open-source bong designs. To create your own 3D printed bong, you'll need a 3D printer. There is an increasingly large selection of home-use 3D printers for just a few hundred dollars. You'll also want to invest in some quality PLA (polylactic acid) printer filament - this is what your pipe will be made out of. PLA is the cheapest and most easily accessible building material for 3D printing.

If you don't have a 3D printer (and don't have any interest in buying one), you can also find local creative spaces with free-access 3D printers. Even UPS has gotten in on the 3D printing game, having opened locations across the United States where customers can upload their designs to be printed on-site. Once you have access to a 3D printer, you can use open-source designs easily found online to begin crafting your ideal bong. For example, if you find a Thingiverse bong design that you want to print, all you have to do is download the open-source file and upload it to the 3D printer software you have along with your 3D printer. Of course, you can also create unique designs if you've got the tech chops to make a 3D bong print from scratch.

Do you have a 3D printed bong and/or have you made your own? Let us know how it works, what you needed to create your own, and what tips you have for anyone looking to print their own cannabis accessories. You can even share your creations with us. Comment below!